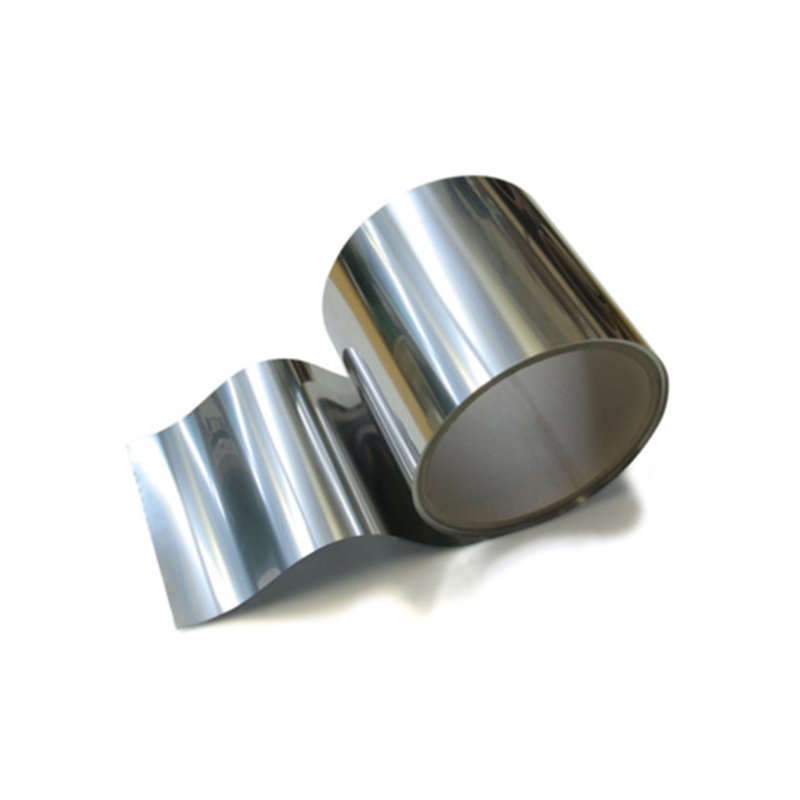

Gasket steel stainless ukugqiba umgangatho wemveliso ngqo ukuthengisa

Iipropati Zomzimba

1. Kukho i-chloride ion kwindawo yokusebenza.

I-ion ye-chloride ifumaneka kwityuwa, ukubila, amanzi olwandle, umoya, umhlaba, njl njl.

Ngoko ukusetyenziswa kwemeko yensimbi engenasici ineemfuno, kunye nesidingo sokusula rhoqo, ukususa uthuli, ukugcina ucocekile kwaye womile.(Oku kumnika "ukusetyenziswa okungafanelekanga.")

Kukho umzekelo e-United States: ishishini lasebenzisa isikhongozeli se-oki ukubamba isisombululo esine-ion ye-chloride.Ikhonteyina ibisetyenziswa ngaphezulu kweminyaka elikhulu kwaye bekucetywe ukuba itshintshwe ngoo-1990.Ngenxa yokuba izinto ze-oki zazingeyomihla yangoku ngokwaneleyo, isitya saye sagqwala kwaye savuza iintsuku ezili-16 emva kokutshintshwa kwentsimbi engatyiwayo.

2. Akukho unyango lwesisombululo.

Izinto ze-alloy azizange zichithwe kwi-matrix, okubangele umxholo ophantsi we-alloy kwisakhiwo se-matrix kunye nokunganyangeki kwe-corrosion.

3. Izinto ezinjalo ezingenayo i-titanium kunye ne-niobium zinomkhuba wendalo we-intergranular corrosion.

Ukongezwa kwe-titanium kunye ne-niobium, edibene nonyango oluzinzileyo, kunokunciphisa ukubola kwe-intergranular.

Emoyeni okanye kwimichiza ye-corrosion medium inokumelana nokubola kwentsimbi ephezulu yealloy, intsimbi engenasiphene iyindawo entle kunye nokumelana nokutyiwa kokutya, akufuneki ukuba ibekwe kunye nolunye unyango olungaphezulu, kwaye idlale iipropathi zendalo zentsimbi engatyiwayo, esetyenziswa imiba emininzi yohlobo lwentsimbi, edla ngokubizwa ngokuba yintsimbi engenasici.Egameni lokusebenza kwentsimbi ye-chromium eyi-13, i-18-8 ye-chromium nickel yensimbi kunye nenye insimbi ephezulu ye-alloy.

Ukusuka kwindawo yokujonga i-metallographic, ngenxa yokuba insimbi engenasici iqulethe i-chromium kunye nomphezulu wokwakheka kwefilimu ye-chromium encinci kakhulu, ifilimu ihlukaniswe ne-oksijini ekuhlaselweni kwentsimbi yokumelana nokubola.

Ukugcina ukuxhathisa kwe-corrosion ekhoyo kwinsimbi engenasici, intsimbi kufuneka ibe ne-chromium engaphezu kwe-12%.

I-304Stainless steel Shim Plates yintsimbi yendalo yonke, esetyenziswa ngokubanzi ekwenzeni izixhobo kunye neengxenye ezifuna iipropati ezilungileyo ezibanzi (ukumelana nokubola kunye nokubumba).

I-304 insimbi engenasici yi-brand yensimbi engenasici eyenziwe ngokuhambelana nemigangatho ye-ASTM e-United States.I-304 ilingana ne-China 0Cr19Ni9 (0Cr18Ni9) yentsimbi engenasici.I-304 iqulethe i-19% yechromium kunye ne-9% ye-nickel.

I-304 yeyona nto isetyenziswa kakhulu intsimbi engenasici/ ekwazi ukumelana nobushushu.Isetyenziswa kwizixhobo zokuvelisa ukutya/izixhobo zekhemikhali zexiton/amandla enyukliya, njl.

I-304 ihambelana ne-brand yaseTshayina 0Cr18Ni9,1Cr18Ni9Ti, umxholo wekhabhoni ≤0:08%

I-304Lstainless steel Shim Plates iyinhlukano ye-304stainless steel Shim Plates insimbi engenasici enomxholo ophantsi wekhabhoni kwaye isetyenziselwa ukufakwa kwe-welding.Umxholo ophantsi wekhabhoni unciphisa imvula ye-carbides kwindawo echaphazelekayo ukushisa kufuphi ne-weld, engakhokelela kwi-corrosion ye-intergranular (i-welding erosion) kwinsimbi engenasici kwezinye iindawo.

Iiparamitha

| T | ubulukhuni | ubulukhuni | Imvula yenza lukhuni imo yonyango lobushushu | conductive% | ||||||

| ubulukhuni | ubulukhuni | Amandla esivunoN/mm | Amandla okuqinaN/mm | elongation% | Unyango lobushushu | ubunzimaHV | Amandla esivunoN/mm | Amandla okuqinaN/mm | ||

| 301-CSP | 1/2H | 340±30 | ≥510 | ≥930 | ≥10 | - | - | - | - | 2.3 |

| 3/4H | 400±30 | ≥745 | ≥1130 | ≥5 | - | - | - | - | 2.3 | |

| H | 460±30 | ≥1030 | ≥1320 | - | - | - | - | - | 2.3 | |

| EH | 510±20 | ≥1275 | ≥1570 | - | - | - | - | - | 2.3 | |

| SEH | ≥530 | ≥1450 | ≥1740 | - | - | - | - | - | 2.3 | |

| 304-CSP | 1/2H | 280±30 | ≥470 | ≥780 | ≥6 | - | - | - | - | 2.3 |

| 3/4H | 340±30 | ≥665 | ≥930 | ≥3 | - | - | - | - | 2.3 | |

| H | ≥370 | ≥880 | ≥1130 | - | - | - | - | - | 2.3 | |

| 631-CSP | 0 | ≤200 | - | ≤1030 | ≥20 | TH1050RH950 | ≥345≥392 | ≥960≥1030 | ≥1140≥1230 | 2.3 |

| 1/2H | 375±25 | - | ≥1080 | ≥5 | CH | ≥380 | ≥880 | ≥1230 | 2.3 | |

| 3/4H | 425±25 | - | ≥1180 | CH | ≥450 | ≥1080 | ≥1420 | 2.3 | ||

| H | ≥450 | - | ≥1420 | CH | ≥530 | ≥1320 | ≥1720 | 2.3 | ||