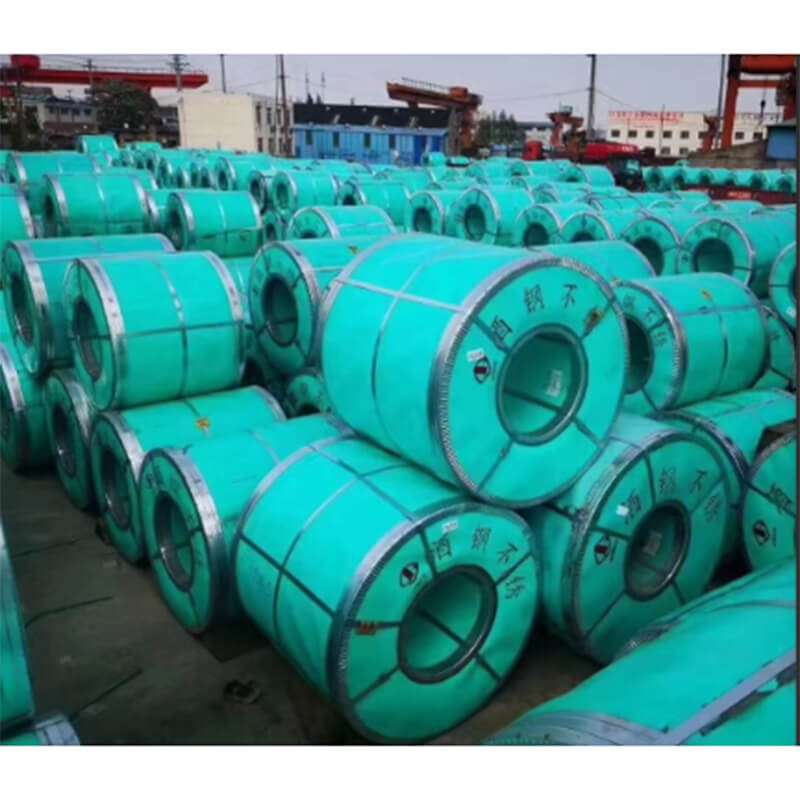

I-2205 yentsimbi yentsimbi yePlati ye-Duplex yentsimbi yepleyiti

Inkcazo

Uxinzelelo lwe-corrosion resistance ye-2205 (00Cr22Ni5Mo3N) i-duplex yensimbi engenasici kwisisombululo se-chloride engathathi hlangothi kunye ne-H2S ingcono kune-304L, i-316L i-austenitic stainless steel kunye ne-18-5Mo duplex steel stainless.Ngaba kubanda, ukusetyenzwa kushushu kunye nokwenza, i-weldability elungileyo, intsimbi ifanelekile kwizinto zokwakha, okwangoku ihlabathi kwi-double-phase stainless steel grade esetyenziswa kwibakala eliqhelekileyo.

I-2205 ipleyiti yensimbi engenasici (00Cr22Ni5Mo3N) i-duplex yensimbi engenasici yenziwe nge-21% ye-chromium, i-2.5% ye-molybdenum kunye ne-4.5% ye-nickel-nitrogen alloy.Inamandla aphezulu, ukuqina kwempembelelo elungileyo kunye nokudityaniswa okulungileyo kunye nokuxhathisa kwi-corrosion yasekhaya.Amandla emveliso ye2205 duplex steel stainless iphindwe kabini kune-austenitic stainless steel.Le propati ivumela abaqulunqi ukuba banciphise ubunzima xa beyila iimveliso, okwenza le ngxube ifikeleleke ngaphezu kwe-316,317L.Le ngxubevange ilungele ukusetyenziswa kwiqondo lobushushu -50°F/+600°F.Izicelo ezingaphaya kolu luhlu lweqondo lokushisa zingaphinda ziqwalasele le ngxube, kodwa kukho imida, ngakumbi xa isetyenziswe kwizakhiwo ezidibeneyo.

2205 (00Cr22Ni5Mo3N) Iimpawu zeNtsimbi yeDuplex

1. Xa kuthelekiswa ne-316L kunye ne-317L i-austenitic steel stainless, i-2205 i-alloy inomsebenzi ongcono wokumelana nokubola kunye ne-crack corrosion, inokumelana ne-corrosion ephezulu, xa kuthelekiswa ne-austenite, i-coefficient yokwandisa i-thermal iphantsi, i-conductivity ephezulu ye-thermal.

2. Xa kuthelekiswa ne-austenitic stainless steel, amandla oxinzelelo lwe-duplex 2205 ipleyiti yensimbi engenasici iphindwe kabini kune-austenitic stainless steel.Xa kuthelekiswa ne-316L kunye ne-317L, umyili unokunciphisa ubunzima bayo.I-alloy ye-2205 ilungele ukusetyenziswa kwi- -- 50 ° F / + 600 ° F kuluhlu lobushushu kunye namaqondo obushushu asezantsi phantsi kwezithintelo eziqinileyo (ingakumbi kwizakhiwo ezidityanisiweyo).

I-2205 (00Cr22Ni5Mo3N) Ukumelana nokuTyakala

1. Umhlwa olinganayo

Ngenxa yomxholo we-chromium (22%), umxholo we-molybdenum (3%) kunye nomxholo we-nitrogen (0.18%), ukuxhatshazwa kwe-corrosion ye-2205 kuphezulu kune-316L kunye ne-317L kwiindawo ezininzi.

2. Ukumelana nomhlwa kwendawo

Umxholo we-chromium, i-molybdenum kunye ne-nitrogen kwi-double-phase iron 2205 yenza ukuba ixhathise kakhulu kwi-spot kunye ne-gap corrosion kwi-oxidizing kunye ne-acidic solutions.

3. Uxinzelelo lwe-corrosion resistance

I-duplex microstructure yensimbi engenasici iluncedo ekuphuculeni ukuchaswa kokuqhekeka kwensimbi engenasici.I-Chloride stress corrosion ivela kwi-austenitic stainless steel kwiqondo lobushushu elithile, uxinzelelo, ioksijini kunye nobukho bekloridi.Ngenxa yokuba le miqathango inzima ukulawula, ukusetyenziswa kwe-304L, i-316L kunye ne-317L ilinganiselwe kule nkalo.

4. Ukudinwa kwe-Anti-corrosion

Amandla aphezulu kunye nokumelana nokubola kwe-duplex steel 2205 kuyenza ibe namandla aphezulu okudinwa.Izixhobo zokucubungula zichaphazeleka kwiindawo ezinobungozi kunye nemijikelezo yokulayisha, kwaye iimpawu ze-2205 zifanelekile kwizicelo ezinjalo.

2205 (00Cr22Ni5Mo3N) Ukusetyenziswa

· Iinqanawa zoxinzelelo, iitanki zokugcina uxinzelelo oluphezulu, imibhobho yoxinzelelo oluphezulu, abatshintshisi bobushushu (ishishini lokulungisa imichiza).

· Ufakelo lwemibhobho yeoli nerhasi kunye nokutshintsha ubushushu.

· Inkqubo yokucoca ugutyulo.

· Abahluli boshishino lwePulp kunye nephepha, izixhobo zokujikijelwa, ukugcinwa kunye neenkqubo zonyango.

· Iishafti ezijikelezayo, iirola zokucinezela, iibhleyidi, ii-impellers, njl.

· Isingxobo somthwalo wenqanawa okanye welori

· Izixhobo zokulungisa ukutya